Материал из Википедии — свободной энциклопедии

| М-100 | |

| завод № 26 (Рыбинск) | |

| 1935—1940 | |

| 12-цилиндровый, рядный, V-образный, карбюраторный | |

| Технические характеристики | |

| 36,03 л | |

| 150 мм | |

| 170 мм | |

| 12 | |

| одноступенчатый односкоростной приводной центробежный нагнетатель | |

| этилированный бензин 2Б-70 | |

| водяное | |

| Размеры | |

М-100 (Испано-Сюиза 12Ybrs) — советский авиационный двигатель, лицензионная копия французского авиамотора Испано-Сюиза 12Ybrs (англ. Hispano-Suiza 12Y).

Двигатель М-100 устанавливался на серийных бомбардировщиках СБ, опытных самолетах И-17бис и «Сталь-7».

Двигатель имел следующие модификации:

ru.bywiki.com

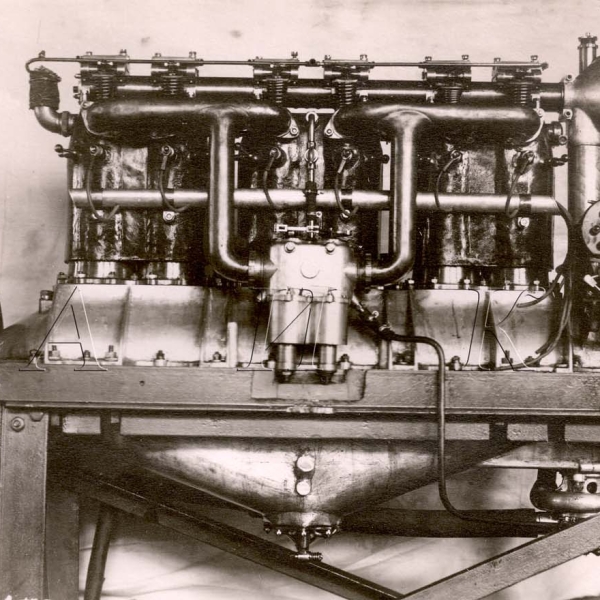

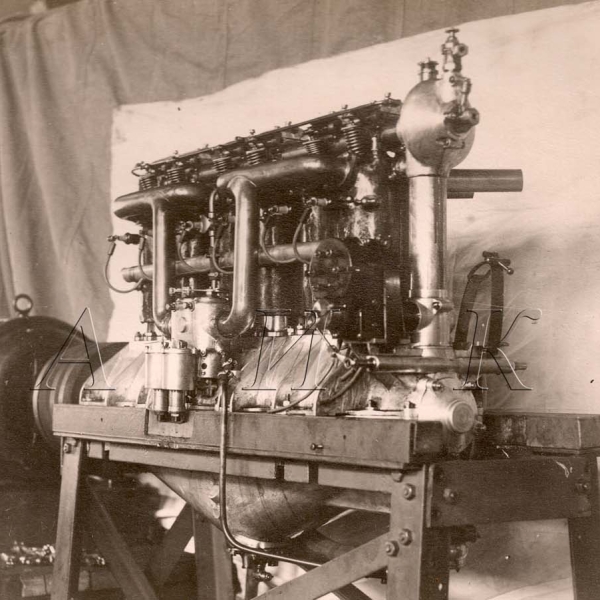

Поршневой авиационный двигатель «ДЕКА» М-100.

Разработчик: инж. Воробьев Страна: Российская Империя Год постройки: 1916

В августе 1916 года на находившемся в Александровске (с 1921 года — г. Запорожье) заводе Петроградского «Акционерного общества «Дюфлон, Константинович и Ко» (сокращенно «ДЕКА») был испытан первый авиамотор «ДЕКА» М-100 — вертикальный, шестицилиндровый, однорядный, водяного охлаждения, типа «Mercedes». Его чертежи создали под руководством инженера Воробьева. Интересно отметить, что в этой работе принимал участие студент Московского Императорского высшего технического училища Владимир Климов, будущий генеральный конструктор двигателей «ВК», основатель ОКБ-117 (ныне ОАО «Климов», Санкт-Петербург), проходивший в то время заводскую практику.

Первые пять шестицилиндровых однорядных моторов «ДЕКА» М-100 с запчастями и одним дополнительным комплектом надо было сдать к концу августа 1916 года. Дело оказалось очень непростым: немецкая конструкция «не стыковалась» ни с принятой у нас технологией и системой допусков и посадок, ни с возможностями российских и американских станков. Надо было разобраться в использованных немецкими конструкторами материалах и подобрать им замену отечественного производства с учетом необходимости обеспечения прочности, жаро- и износостойкости, а также фрикционных свойств. Возглавил работу по «адаптации» мотора «Mercedes» к нашему производству всё тот же инженер Воробьев, а освоением более мощного двигателя «Benz» занимался инженер Киреев.

Как указывается выше завод Петроградского «Акционерного общества «Дюфлон, Константинович и Ко» со сборкой первого двигателя «ДЕКА» справился. Генерал-майор Пневский доложил в Петербург: «…первый стосильный мотор, сделанный целиком из русских материалов, был пущен в ход и дал вполне удовлетворительные результаты.» Завод приступил к выполнению договора в полном объеме.

И хотя к тому времени канцелярии Управления воздушного флота удалось навести определенный порядок в своей «бухгалтерии», заставить сделать это производителей аэропланов не удалось. Да и в последовавших в 1917 году событиях погибли многие и многие архивные дела. Поэтому, к сожалению, невозможно отыскать информацию о том, на какие конкретно экземпляры самолета «Илья Муромец» были установлены первые моторы «ДЕКА».

Двигатель «ДЕКА» М-100.

Двигатель «ДЕКА» М-100.

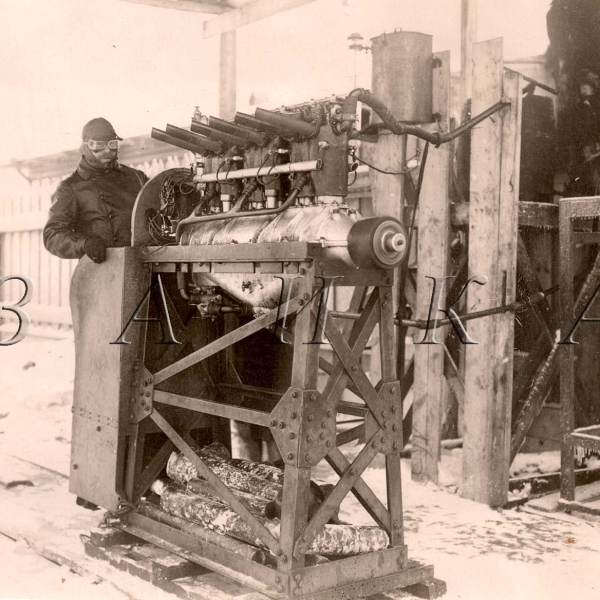

Двигатель «ДЕКА» М-100 на стендовых испытаниях.

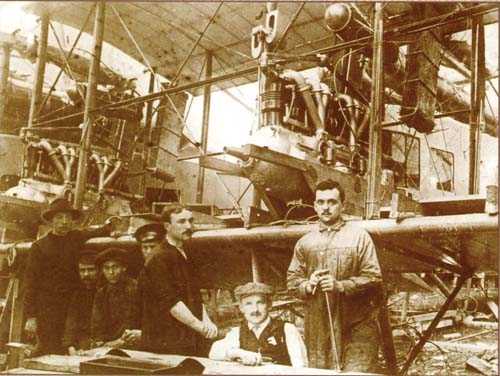

Монтаж двигателей «ДЕКА» на самолет «Илья Муромец».

.

.

Список источников:И.Иванов. История завода «Мотор-Сич».С.Г.Мороз. Пламенное сердце для «Ильи Муромца». Журна «Наука и Техника» № 8 за 2012 г.Фотоархив Петра Заики.

xn--80aafy5bs.xn--p1ai

1. Компрессор – A gas compressor is a mechanical device that increases the pressure of a gas by reducing its volume. An air compressor is a type of gas compressor. Compressors are similar to pumps, both increase the pressure on a fluid and both can transport the fluid through a pipe, as gases are compressible, the compressor also reduces the volume of a gas. Liquids are relatively incompressible, while some can be compressed, the action of a pump is to pressurize. The main types of gas compressors are illustrated and discussed below and they can be either stationary or portable, can be single or multi-staged, and can be driven by electric motors or internal combustion engines. Small reciprocating compressors from 5 to 30 horsepower are commonly seen in applications and are typically for intermittent duty. Larger reciprocating compressors well over 1,000 hp are commonly found in large industrial, discharge pressures can range from low pressure to very high pressure. Another type of reciprocating compressor is the swash plate compressor, which uses pistons moved by a swash plate mounted on a shaft, household, home workshop, and smaller job site compressors are typically reciprocating compressors 1½ hp or less with an attached receiver tank. Rotary screw compressors use two meshed rotating positive-displacement helical screws to force the gas into a smaller space and these are usually used for continuous operation in commercial and industrial applications and may be either stationary or portable. Their application can be from 3 horsepower to over 1,200 horsepower, rotary screw compressors are commercially produced in Oil Flooded, Water Flooded and Dry type. The efficiency of rotary compressors depends on the air drier, rotary vane compressors consist of a rotor with a number of blades inserted in radial slots in the rotor. The rotor is mounted offset in a housing that is either circular or a more complex shape. As the rotor turns, blades slide in and out of the slots keeping contact with the wall of the housing. Thus, a series of increasing and decreasing volumes is created by the rotating blades, rotary Vane compressors are, with piston compressors one of the oldest of compressor technologies. With suitable port connections, the devices may be either a compressor or a vacuum pump and they can be either stationary or portable, can be single or multi-staged, and can be driven by electric motors or internal combustion engines. A rotary vane compressor is well suited to electric drive and is significantly quieter in operation than the equivalent piston compressor. Rotary vane compressors can have mechanical efficiencies of about 90%, rolling piston forces gas against a stationary vane. A scroll compressor, also known as pump and scroll vacuum pump

2. Hispano-Suiza – Hispano-Suiza was a Spanish automotive/engineering company and, after World War II, a French aviation engine and components manufacturer. It is best known for its cars and aviation engines pre-World War II. In 1923, its French subsidiary became a partnership with the Spanish parent company. In 1946, the Spanish parent company sold all its Spanish automotive assets to Enasa, in 1968, the French arm was taken over by the aerospace company Snecma, now a part of the French SAFRAN Group. Hispano-Suiza designed the first 4-cylinder 16-valve engine and the car considered to have been the first sports car, in 1898 a Spanish artillery captain, Emilio de la Cuadra, started electric automobile production in Barcelona under the name of La Cuadra. In Paris, De la Cuadra met the Swiss engineer Marc Birkigt, La Cuadra built their first gasoline-powered engines from a Birkigt design. At some point in 1902, the ownership changed hands to J. Castro and became Fábrica Hispano-Suiza de Automóviles, yet another restructuring took place in 1904, creating La Hispano-Suiza Fábrica de Automóviles, under Castros direction, also based in Barcelona. Four new engines were introduced in the year and a half, a 3. 8-litre and 7. 4-litre four-cylinder. This company managed to avoid bankruptcy and its largest operations remained in Barcelona until 1946, other factories in Spain were at Ripoll, Seville, and Guadalajara. France was soon proving to be a market for Hispanos luxury cars than Spain. In 1911, a factory called Hispano France began operating in the Paris suburb of Levallois-Perret. Production was moved to larger factories at Bois-Colombes, under the name Hispano-Suiza in 1914, with the start of World War I, Hispano-Suiza turned to the design and production of aircraft engines under the direction of Marc Birkigt. His chief engineer during this period was another Swiss, Louis Massuger, traditionally, aircraft engines were manufactured by machining separate steel cylinders and then bolting these assemblies directly to the crankcase. Birkigts novel solution called for the block to be formed from a single piece of cast aluminum. Manufacturing an engine in this way simplified construction and resulted in a lighter, thus, Birkigts new construction method created the first practical, and what are commonly known today as, cast block engines. Another major design feature, for the later HS. 8B line was the use of a propeller shaft for both the 8B and 8C gear-reduction versions, which when used for the HS. After World War I, Hispano-Suiza returned to manufacturing and in 1919 they introduced the Hispano-Suiza H6. Licences for Hispano-Suiza patents were much in demand from prestige car manufacturers world-wide, Rolls-Royce used a number of Hispano-Suiza patents

3. АНТ-40 – The Tupolev ANT-40, also known by its service name Tupolev SB and development co-name TsAGI-40, was a high speed twin-engined three-seat monoplane bomber, first flown in 1934. The Tupolev design was advanced but lacked refinement, much to the dismay of crews, maintenance personnel and of Stalin and it was produced in Soviet Union and licensed production in Czechoslovakia also took place. Many versions saw extensive action in Spain, the Republic of China, Mongolia, Finland and it was also used in various duties in civil variants, as trainers and in many secondary roles. Successful in the Spanish Civil War because it outpaced most fighters, by June 1941,94 percent of bombers in the Red Army air force were SBs. In 1933 the Soviet Air Force ministry issued a requirement for a high-speed bomber. Work on this proposal at TsAGI began in January 1934, the SB was designed and developed in the Tupolev KB by a team led by A. A. Arkhangelski. Two versions were planned – with Wright Cyclone radial engines, the skills gained in the design of the MI-3 and DI-8 aircraft were widely used. The first two prototypes were designed as ANT-40.1 and ANT-40.2, the second Hispano-Suiza powered aircraft, the ANT-402 was considered a production prototype, and its performance was impressive. On seeing these placards, Ordzhonikidze summoned Tupolev to a meeting at the Kremlin to discuss these shortfalls, the first production aircraft, designated SB, rolled off the production line before the end of 1935, and before ANT-402 had completed its flight test programme. The aircraft entered production in 1936, and was produced in two plants, State Aircraft Factory No 22 at Moscow and No 125 at Irkutsk until 1941. Giving excellent performance in the Spanish Civil War, it acquired the popular name Katyusha, the version of the SB to be supplied to, and subsequently license-built as the Avia B-71 was the SB 2M-100A but fitted with the Avia-built Hispano-Suiza 12-Ydrs engine. A single 7.92 mm ZB-30 machine gun supplanted the twin ShKAS machine guns in the nose, sixty aircraft were to be flown to Czechoslovakia by mid-1938. The planned licensed production program took a leisurely course, despite the increasingly dangerous political situation. By 15 March 1939, when the German Wehrmacht occupied Bohemia and Moravia, development of the SB continued, meanwhile, with revisions being made to reflect the lessons of early operations in Spain. As problems were encountered in converting pilots to fly the SB, a trainer version, problems were also encountered with the armament, the nose guns having limited traverse and so being little use against head-on attacks and later aircraft were modified with a better field of fire. From 1940, the gun position was replaced by an enclosed turret, while the ventral gun position. The aircraft was also fitted with improved engines. Alexeev set an altitude record of 12,246 m with load of 1,000 kg in an M-103 powered SB

4. АИ-14 – The Ivchenko AI-14 is a nine-cylinder, air-cooled, radial piston engine designed in the Soviet Union to power aircraft. Its main variant is the AI-14R, which underwent state trials in December 1950 and was used in many types of light aircraft, there was also an AI-14V variant for helicopters and other applications. The AI-14R is typically used with a propeller and is started with compressed air. Apart from the Soviet Union, a version of the AI-14R, has been produced by WSK-Kalisz in Poland from 1956 until 2007. The AI-14RF was a variant uprated by Ivan Vedeneyev to 300 hp and its further development is the Vedeneyev M14P family of engines. Another modified version is the Czechoslovak Avia M462, which powers the Zlín Z37 agricultural aircraft, the Zhuzhou HS-6 was the designation for AI-14 Licence production in China.9,1 List of aircraft engines Gunston, Bill

5. АИ-26 – The Ivchenko AI-26 is a seven-cylinder air-cooled radial engine used in early Soviet helicopters and later used in light utility aircraft. The AI-26 engine was designed by A. G Ivchenko in 1945 with the early designation M-26, like the Shvetsov ASh-21 which is basically one bank of cylinders from the Shvetsov ASh-82, the AI-26 was also influenced by the ASh-82. The AI-26 retained the bore, stroke and displacement of the ASh-21 while incorporating new features peculiar to its role and this similarity allowed the AI-26 to use the same production jigs as the ASh-21 and ASh-82 which reduced costs and simplified production. The engine was envisioned as an engine, but the early test models lacked the necessary equipment to facilitate this role, such as an auxiliary cooling fan, reduction gears. The GR suffix means Gelikopter, or helicopter, engine testing was completed by early 1946 and by 1947 helicopter testing had begun. In late 1947 the decision to mass-produce the engine was made, between 1947 and the 1970s some 1,300 AI-26GRs were produced. The AI-26V model was produced in Poland during the 1960s as the LiT-3

6. АМ-34 – The Mikulin AM-34 was a Soviet mass-produced, liquid-cooled, aircraft engine. Before the war, the Russian aero engine industry was engaged in producing engines of foreign design, notably Wright, Bristol, Hispano-Suiza. Several engines of so-called original design have been developed, although these were largely based on foreign models. The M-34 was thought to have been designed in Italy by Fiat for the Russians. Its initial development was troubled, but it became one of the most successful Soviet aircraft engines of the 1930s. A version of the model was adapted for use in several prototype heavy tanks in 1939. The M-34 began development in 1928 as a replacement for the Mikulin M-17 and it had similar dimensions and attachment points, but was otherwise an entirely new design. It was a direct-drive, block-type engine with the block connected by long internal studs with centrally coupled articulated connecting rods. The development of the process was prolonged, with the engineering drawings not completed until April 1931. The first engine was delivered to TsIAM on 21 September 1931 for bench testing with imported carburetors and it began state testing in November 1931, but failed. It was submitted again a year later with Soviet-designed K-34 carburetors and it was resubmitted in January 1933, but again failed. It was flight-tested in a Tupolev TB-3 in October 1933, despite these failures it began production in 1932 at Factory No.24 in Moscow, and 64 engines had been delivered by the end of the year. 790 were built the year, and it was exhibited in Paris as an achievement of the Soviet aviation industry. The M-34 was redesignated with Alexsander Mikulins initials as the AM-34 on 9 August 1936 in honor of his achievement, the first installation, designated ATsN-1, used an auxiliary M-34 fitted inside the fuselage to drive a central supercharger with ducts leading to the engines in the wings. This was flight-tested in a Tupolev TB-3 in 1935 and it was adapted for use in a Petlyakov Pe-8 bomber prototype with a smaller Klimov M-100 engine substituted for the M-34 as the ATsN-2. It was flight-tested during 1938–39, but was not approved for production, the same idea was revived in 1943 by Nazi Germany with the Henschel Hs 130E bomber prototype series, with the Höhen-Zentrale Anlage unit. Like the BMW VI and the Mikulin M-17, the AM-34FRN, combined with a number of other changes power significantly increased in most models to 1,200 horsepower. Development of a version for torpedo boats began in 1932 as the GM-34

7. АМ-35 – The Mikulin AM-35 was a 1930s Soviet piston aircraft engine. Derived from the AM-34FRN, the AM-35 entered production in 1940 and was used on the MiG-1, the engine was very similar to the AM-38F of the Ilyushin Il-2, and built in the same plant. It was for this fact that Mikulin was forced to focus production on the AM-38F, MiG-1 MiG-3 Petlyakov Pe-8 Data from Kotelnikov. Type, Piston V12 engine with 60° angle Bore, 160mm Stroke, displacement,46.6 kW/L Compression ratio,7.0,1 Specific fuel consumption,0.46 kg/km calculated,0.38 kg/km observed

8. АЧ-30 – The Charomskiy ACh-30 was a Soviet aircraft diesel engine developed during World War II. The initial version was not very satisfactory and it was cancelled when its factory was forced to evacuate in the autumn of 1941, the ACh-30 was a development of the experimental AN-1RTK turbo-supercharged diesel engine that had begun development in the early 1930s. It was initially designated as the AD-5 when development began in the attached to Factory No.82 at Tushino Airport in 1939. Construction of the first five prototypes began at the end of that year, preparations to begin series manufacture at Factory No.82 began in May 1940, but actual production was delayed until 1941 when forty-four were built as the M-30. Production was planned to be transferred to the Kharkov Tractor Factory, the M-30 had proven to be unsatisfactory in service, as it was unreliable and troublesome at high altitudes and in cold conditions. Specific problems were its failure to deliver full rpm and it suffered from oil blowouts, therefore, production was cancelled when Factory No.82 was forced to evacuate in the fall of 1941 because of the German advance on Moscow. Production was reinitiated in the workshops of Factory No.82 by Factory No.500 in June 1942. Development of supercharged versions began about the time, using geared, centrifugal type superchargers adapted from the Mikulin AM-38. That from the AM-38 was more successful and was put into production as the M-30B, thirty-five incomplete M-30 engines were modified beginning in August into M-30Bs and then thirty-four M-30Bs were produced during the rest of 1942. Oddly the ACh-30B, as the engine was now known, was not formally accepted for production until 19 June 1943. Factory No.45 began production in the quarter of 1943. Some 1450 ACh-30Bs were built before production ended at both factories in September 1945, the ACh-30B was tested as a motorjet where the jet engines compressor was driven by an incorporated piston engine. It was bench tested from June 1944 through May 1945, but was never installed in any aircraft, the jet engines thrust was 1,925 lbf and the equivalent horsepower of the combination was 4,500 hp. Versions of the ACh-30 were evaluated on the Ilyushin Il-6 and the ANT-67, a version of the Tupolev Tu-2. It was also proposed for use on the Tupolev Tu-8S and the MN executive transport, AD-5, M-30, ACh-30 – four turbochargers, but no supercharger. Weight,1,200 kg, Power,1,500 hp, Power,1,750 hp M-30B, ACh-30B – main production variant,1450 built. M-30D – boosted version for an aircraft with 2,000 hp. Factory No.500 ordered to develop this version, but no information is known

wikivisually.com

Двигатель М-100 устанавливался на серийных бомбардировщиках СБ, опытных самолетах И-17бис и «Сталь-7».

Двигатель имел следующие модификации:

| АИ-4Г (АИ-4В) · АИ-10 · АИ-14 · АИ-26 · АМ-34 · АМ-35 · АМ-37 · АМ-38 · АМ-39 · АМ-42 · АН-1 · АЧ-30 · АШ-21 · АШ-62 · АШ-73 · АШ-82 · АШ-83 · АШ-2 · ВАЗ-416 · ВАЗ-426 · ВАЗ-526 · ВД-4К · ДН-200 · М-1 · М-2 · М-3 · М-5 · М-11 · М-15 · М-17 · М-22 · М-25 · М-32 · М-40 · М-62 · М-63 · М-71 · М-85 · М-86 · М-87 · М-88 · М-89 · М-100 · М-103 · М-105 (ВК-105) · М-106 (ВК-106) · М-107 (ВК-107) · ВК-108 · М-224 · М-250 · М-251ТК · М-501 · МБ-100 · МГ-31 · ММ-1 · П-032 | ||||||||||||||||

| АЛ-7 · АЛ-21 (АЛ-21Ф-3) · АМ-3 (РД-3) · ВД-7 (РД-7) · ВК-1 (РД-45) · РД-9 (АМ-9) · РД-36 · РД-41 · РД-60 · РД-500 · Р-11-300 · Р-13 · Р-15 · Р-25-300 · Р27В-300 · Р28В-300 · Р-29-300 · Р-35 · Р-95Ш · Р-195 · ТР-1 | ||||||||||||||||

| ||||||||||||||||

| АИ-20 · АИ-20М · АИ-24 · АИ-450 · ВК-2 · ВК-1300 · ГТД-350 · Д-25 · Д-27 · Д-136 · Д-236 · НК-12 · РД-600 · ТВа-3000 · ТВ2-117 · ТВ3-117 · ТВ7-117 · ТВД-10 · ТВД-20 · ТВД-150 · ТВ-0-100 · ГТД-3 · ТВД-1500 · ТВ-Д · ТВ-О · ТВ-128 | ||||||||||||||||

| АИ-8 · АИ-9 · АИ-450-МС · ВГТД-2 · ВГТД-43 · ВСУ-10 · ГТД-1 · ГТД-5 · ГТДЭ-117 · РУ-19А-300 · ТА-4ФЕ · ТА-6 · ТА-8 · ТА-12 · ТА-14 · ТА18-100 · ТА18-200 |

М-100 (двигатель) Информация Видео

М-100 (двигатель) Просмотр темы.М-100 (двигатель) что, М-100 (двигатель) кто, М-100 (двигатель) объяснение

There are excerpts from wikipedia on this article and video

www.turkaramamotoru.com