1. Оппозитный двигатель – A flat engine is an internal combustion engine with horizontally-opposed cylinders. Typically, the layout has cylinders arranged in two banks on either side of a crankshaft and is otherwise known as the boxer. The concept was patented in 1896 by engineer Karl Benz, who called it the contra engine, a boxer engine should not be confused with the opposed-piston engine, in which each cylinder has two pistons but no cylinder head. Also, if an engine is canted 90 degrees into the horizontal plane. Horizontal inline engines are common in industrial applications such as underfloor mounting for buses. True boxers have each crankpin controlling only one piston/cylinder while the 180° engines, the 180° engine, which may be thought of as a type of V engine, is quite uncommon as it has all of the disadvantages of a flat engine, and few of the advantages. In 1896, Karl Benz invented the first internal combustion engine with opposed pistons. He called it the engine, as the action of each side opposed the action of the other. This design has since called the boxer engine because each pair of pistons moves in. The boxer engine has pairs of pistons reaching TDC simultaneously and these engines do not require a balance shaft or counterweights on the crankshaft to balance the weight of the reciprocating parts, which are required in most other engine configurations. However, in the case of engines with fewer than six cylinders. Other engine configurations with natural dynamic balance include the straight-six, the straight-eight, the V12, Boxer engines tend to be noisier than other common engines for both intrinsic and other reasons. In cars, valve clatter from the compartment is not damped by air filters or other components. Multi-cylinder boxer layouts have proved to be suited as light aircraft engines, as exemplified by Continental, Lycoming, Rotax, Jabiru. An important factor in aircraft use is the flat engines absence of vibration, general aviation aircraft often use air-cooled flat-four and flat-six engines made by companies such as Lycoming and Continental. Ultralight and microlight aircraft often use such as the Rotax 912. During the Second World War, Boxer engines were used as a motor for the first German jet engines to power up the engine at cranking speed. It was a short stroke design so it could fit in the hub of the turbine compressor

2. Коленчатый вал – A crankshaft—related to crank—is a mechanical part able to perform a conversion between reciprocating motion and rotational motion. In a reciprocating engine, it translates reciprocating motion of the piston into rotational motion, whereas in a reciprocating compressor, a Roman iron crank of yet unknown purpose dating to the 2nd century AD was excavated in Augusta Raurica, Switzerland. The 82.5 cm long piece has fitted to one end a 15 cm long bronze handle, the accompanying inscription is in Greek. The crank and connecting rod mechanisms of the other two archaeologically attested sawmills worked without a gear train, al-Jazari described a crank and connecting rod system in a rotating machine in two of his water-raising machines. His twin-cylinder pump incorporated a crankshaft, though the device was unnecessarily complex, the Italian physician Guido da Vigevano, planning for a new crusade, made illustrations for a paddle boat and war carriages that were propelled by manually turned compound cranks and gear wheels. In Renaissance Italy, the earliest evidence of a crank and connecting-rod is found in the sketch books of Taccola. A sound grasp of the motion involved is demonstrated a little later by Pisanello. One of the drawings of the Anonymous of the Hussite Wars shows a boat with a pair of paddle-wheels at each end turned by men operating compound cranks. Crankshafts were also described by Konrad Kyeser, Leonardo da Vinci and his wind-powered sawmill used a crankshaft to convert a windmills circular motion into a back-and-forward motion powering the saw. Corneliszoon was granted a patent for his crankshaft in 1597, large engines are usually multicylinder to reduce pulsations from individual firing strokes, with more than one piston attached to a complex crankshaft. Many small engines, such as found in mopeds or garden machinery, are single cylinder and use only a single piston. A crankshaft is subjected to stresses, potentially equivalent of several tonnes of force. The crankshaft is connected to the fly-wheel, the block, using bearings on the main journals. An engine loses up to 75% of its energy in the form of friction, noise and vibration in the crankcase. The remaining losses occur in the heat and blow by. The crankshaft has a linear axis about which it rotates, typically with several bearing journals riding on replaceable bearings held in the engine block. As the crankshaft undergoes a great deal of sideways load from each cylinder in an engine, it must be supported by several such bearings. This was a factor in the rise of V8 engines, with their shorter crankshafts, the long crankshafts of the latter suffered from an unacceptable amount of flex when engine designers began using higher compression ratios and higher rotational speeds

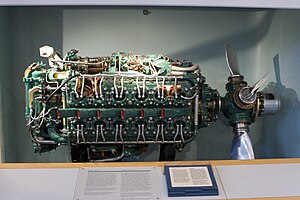

3. Rolls-Royce Eagle (1944) – The Rolls-Royce Eagle was a British 24-cylinder, sleeve valve, H-block aero engine of 46 litre displacement. It was designed and built in the early-1940s by Rolls-Royce Limited and it was liquid-cooled, of flat H configuration with two crankshafts and was capable of 3,200 horsepower at 18 psi boost. The Rolls-Royce design team realised that producing a version of their Griffon V-12 engine would lead to excessively large combustion chambers. The team concluded that a number of small cylinders would be the answer. This layout had previously caused unreliability with the Rolls-Royce Vulture due to the need to fasten four connecting rods in an arrangement to a common big end bearing. The designers finally settled on an H layout with two crankshafts and blade and fork connecting rod attachments, the crankshafts being connected through the speed reduction unit. The new engine followed the layout of the Napier Sabre and similarly used sleeve valves, a two-speed, two-stage supercharger and intercooler were used to compress then cool the air-fuel mixture, following Griffon and Merlin practice. An auxiliary shaft driven by the crankshaft operated the main coolant pump, intercooler coolant pump, pressure and scavenge oil pumps. Piston ring failures and cylinder head sealing problems were experienced during flight testing. Fifteen Eagle 22s were produced to power prototypes of the Westland Wyvern fighter/torpedo bomber due to its intended powerplant, 46H Eagle I - Compression ratio 6.5,1. 46H Eagle II - Modified Eagle I, 46H Eagle 22 - Increased compression ratio,3,500 hp at 3,500 rpm and 28 lb boost. Fifteen engines produced at the Derby Rolls-Royce factory, first flown in a Westland Wyvern on 16 December 1946. An Eagle 22 with some of the cowling panels removed to display the engine can be fitted to Westland Wyvern TF1, VR137, at the Fleet Air Arm Museum. Data from Lumsden Type, 24-cylinder liquid-cooled H-type aircraft piston engine Bore,5.4 in Stroke,5.125 in Displacement,2,807 in³ Length,135.5 in Width,43.4 in Height,50.2985,1 reduction ratio

4. Двигатель – An engine or motor is a machine designed to convert one form of energy into mechanical energy. Heat engines burn a fuel to heat, which is then used to create a force. Electric motors convert electrical energy into motion, pneumatic motors use compressed air. In biological systems, molecular motors, like myosins in muscles, use energy to create forces. The word engine derives from Old French engin, from the Latin ingenium–the root of the word ingenious. Pre-industrial weapons of war, such as catapults, trebuchets and battering rams, were called siege engines, the word gin, as in cotton gin, is short for engine. Most mechanical devices invented during the revolution were described as engines—the steam engine being a notable example. However, the steam engines, such as those by Thomas Savery, were not mechanical engines. In this manner, an engine in its original form was merely a water pump. Devices converting heat energy into motion are commonly referred to simply as engines, examples of engines which exert a torque include the familiar automobile gasoline and diesel engines, as well as turboshafts. Examples of engines which produce thrust include turbofans and rockets, the term motor derives from the Latin verb moto which means to set in motion, or maintain motion. Thus a motor is a device that imparts motion, motor and engine later came to be used largely interchangeably in casual discourse. However, technically, the two words have different meanings, however, rocketry uses the term rocket motor, even though they consume fuel. A heat engine may also serve as a prime mover—a component that transforms the flow or changes in pressure of a fluid into mechanical energy. An automobile powered by a combustion engine may make use of various motors and pumps. Another way of looking at it is that a motor receives power from an external source, simple machines, such as the club and oar, are prehistoric. More complex engines using human power, animal power, water power, wind power and these were used in cranes and aboard ships in Ancient Greece, as well as in mines, water pumps and siege engines in Ancient Rome. The writers of those times, including Vitruvius, Frontinus and Pliny the Elder, treat these engines as commonplace, by the 1st century AD, cattle and horses were used in mills, driving machines similar to those powered by humans in earlier times

5. Двигатель внутреннего сгорания – An internal combustion engine is a heat engine where the combustion of a fuel occurs with an oxidizer in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine, the force is applied typically to pistons, turbine blades, rotor or a nozzle. This force moves the component over a distance, transforming chemical energy into mechanical energy. The first commercially successful internal combustion engine was created by Étienne Lenoir around 1859, firearms are also a form of internal combustion engine. Working fluids can be air, hot water, pressurized water or even liquid sodium, ICEs are usually powered by energy-dense fuels such as gasoline or diesel, liquids derived from fossil fuels. While there are many applications, most ICEs are used in mobile applications and are the dominant power supply for vehicles such as cars, aircraft. Typically an ICE is fed with fossil fuels like natural gas or petroleum products such as gasoline, there is a growing usage of renewable fuels like biodiesel for compression ignition engines and bioethanol or methanol for spark ignition engines. Hydrogen is sometimes used, and can be made from fossil fuels or renewable energy. Various scientists and engineers contributed to the development of internal combustion engines, in 1791, John Barber developed a turbine. In 1794 Thomas Mead patented a gas engine, also in 1794 Robert Street patented an internal combustion engine, which was also the first to use liquid fuel, and built an engine around that time. In 1798, John Stevens built the first American internal combustion engine, in 1807, Swiss engineer François Isaac de Rivaz built an internal combustion engine ignited by electric spark. In 1823, Samuel Brown patented the first internal combustion engine to be applied industrially, in 1860, Belgian Jean Joseph Etienne Lenoir produced a gas-fired internal combustion engine. In 1864, Nikolaus Otto patented the first atmospheric gas engine, in 1872, American George Brayton invented the first commercial liquid-fuelled internal combustion engine. In 1876, Nikolaus Otto, working with Gottlieb Daimler and Wilhelm Maybach, patented the compressed charge, in 1879, Karl Benz patented a reliable two-stroke gas engine. In 1892, Rudolf Diesel developed the first compressed charge, compression ignition engine, in 1926, Robert Goddard launched the first liquid-fueled rocket. In 1939, the Heinkel He 178 became the worlds first jet aircraft, at one time, the word engine meant any piece of machinery — a sense that persists in expressions such as siege engine. A motor is any machine that produces mechanical power, traditionally, electric motors are not referred to as Engines, however, combustion engines are often referred to as motors. In boating an internal combustion engine that is installed in the hull is referred to as an engine, reciprocating piston engines are by far the most common power source for land and water vehicles, including automobiles, motorcycles, ships and to a lesser extent, locomotives

6. Газотурбинный двигатель – A turboshaft engine is a form of gas turbine which is optimized to produce shaft power rather than jet thrust. In concept, turboshaft engines are similar to turbojets, with additional turbine expansion to extract heat energy from the exhaust. They are even similar to turboprops, with only minor differences. Turboshaft engines are used in applications that require a sustained high power output, high reliability, small size. These include helicopters, auxiliary units, boats and ships, tanks, hovercraft. A turboshaft engine may be made up of two major parts assemblies, the gas generator and the power section, the gas generator consists of the compressor, combustion chambers with ignitors and fuel nozzles, and one or more stages of turbine. The power section consists of stages of turbines, a gear reduction system. The gas generator creates the hot expanding gases to drive the power section, depending on the design, the engine accessories may be driven either by the gas generator or by the power section. In most designs, the gas generator and power section are mechanically separate so they can rotate at different speeds appropriate for the conditions. A free power turbine can be a useful design feature for vehicles, as it allows the design to forgo the weight and cost of complex multiple-ratio transmissions. The general layout of a turboshaft is similar to that of a turboprop, the main difference is a turboprop is structurally designed to support the loads created by a rotating propeller, as the propeller is not attached to anything but the engine itself. In contrast, turboshaft engines usually drive a transmission which is not structurally attached to the engine, the transmission is attached to the vehicle structure and supports the loads created instead of the engine. In practice, though, many of the engines are built in both turboprop and turboshaft versions, with only minor differences. Large helicopters use two or three engines for redundancy. The Mil Mi-26 uses two Lotarev D-136 at 11,400 hp each, while the Sikorsky CH-53E Super Stallion uses three General Electric T64 at 4,380 hp each. Early turboshaft engines were adaptations of turboprop engines, delivering power through a shaft driven directly from the gas generator shafts, examples of direct-drive turboshafts include marinised or industrial Rolls-Royce Dart engines. The first examples of a gas engine design ever considered for armoured fighting vehicles. The first true turboshaft engine for helicopters was built by the French engine firm Turbomeca, led by the founder, in 1948, they built the first French-designed turbine engine, the 100-shp 782

7. Двухтактный двигатель – A two-stroke, or two-cycle, engine is a type of internal combustion engine which completes a power cycle with two strokes of the piston during only one crankshaft revolution. This is in contrast to an engine, which requires four strokes of the piston to complete a power cycle. In a two-stroke engine, the end of the combustion stroke, two-stroke engines often have a high power-to-weight ratio, power being available in a narrow range of rotational speeds called the power band. Compared to four-stroke engines, two-stroke engines have a reduced number of moving parts. The first commercial two-stroke engine involving in-cylinder compression is attributed to Scottish engineer Dugald Clerk, however, unlike most later two-stroke engines, his had a separate charging cylinder. The crankcase-scavenged engine, employing the area below the piston as a pump, is generally credited to Englishman Joseph Day. The first truly practical two-stroke engine is attributed to Yorkshireman Alfred Angas Scott, gasoline versions are particularly useful in lightweight or portable applications such as chainsaws and motorcycles. In a two-stroke engine, the transfer from the engine to the cooling system is less than in a four-stroke. Two-stroke petrol engines are preferred when mechanical simplicity, light weight, the Japanese manufacturer Suzuki did the same in the 1970s. Production of two-stroke cars ended in the 1980s in the West, eastern Bloc countries continued until around 1991, with the Trabant and Wartburg in East Germany. They are also common in power tools used outdoors, such as lawnmowers, chainsaws, with direct fuel injection and a sump-based lubrication system, a two-stroke engine produces air pollution no worse than a four-stroke, and it can achieve higher thermodynamic efficiency. Therefore, the cycle has also been used in large diesel engines, most notably large industrial and marine engines, as well as some trucks. Although the principles remain the same, the details of various two-stroke engines differ depending on the type. The design types vary according to the method of introducing the charge to the cylinder, the method of scavenging the cylinder, piston port is the simplest of the designs and the most common in small two-stroke engines. All functions are controlled solely by the covering and uncovering the ports as it moves up. In the 1970s, Yamaha worked out some principles for this system. They found that, in general, widening an exhaust port increases the power by the amount as raising the port. However, there is a limit to the width of a single exhaust port

8. Четырёхтактный двигатель – A four-stroke engine is an internal combustion engine in which the piston completes four separate strokes while turning a crankshaft. A stroke refers to the travel of the piston along the cylinder. The four separate strokes are termed, Intake, also known as induction or suction This stroke of the piston begins at top dead center and ends at bottom dead center. In this stroke the valve must be in the open position while the piston pulls an air-fuel mixture into the cylinder by producing vacuum pressure into the cylinder through its downward motion. Compression, This stroke begins at B. D. C, or just at the end of the suction stroke, in this stroke the piston compresses the air-fuel mixture in preparation for ignition during the power stroke. Both the intake and exhaust valves are closed during this stage, combustion, also known as power or ignition This is the start of the second revolution of the four stroke cycle. At this point the crankshaft has completed a full 360 degree revolution, while the piston is at T. D. C. The compressed air-fuel mixture is ignited by a plug or by heat generated by high compression. This stroke produces mechanical work from the engine to turn the crankshaft, during the exhaust stroke, the piston once again returns from B. D. C. to T. D. C. While the exhaust valve is open and this action expels the spent air-fuel mixture through the exhaust valve. Nikolaus August Otto as a man was a traveling salesman for a grocery concern. In his travels he encountered the internal combustion engine built in Paris by Belgian expatriate Jean Joseph Etienne Lenoir, in 1860, Lenoir successfully created a double-acting engine that ran on illuminating gas at 4% efficiency. The 18 litre Lenoir Engine produced only 2 horsepower, the Lenoir engine ran on illuminating gas made from coal, which had been developed in Paris by Philip Lebon. In testing a replica of the Lenoir engine in 1861 Otto became aware of the effects of compression on the fuel charge, in 1862, Otto attempted to produce an engine to improve on the poor efficiency and reliability of the Lenoir engine. He tried to create an engine that would compress the fuel prior to ignition. Many other engineers were trying to solve the problem, with no success, in 1864, Otto and Eugen Langen founded the first internal combustion engine production company, NA Otto and Cie. Otto and Cie succeeded in creating an atmospheric engine that same year. The factory ran out of space and was moved to the town of Deutz, in 1872, Gottlieb Daimler was technical director and Wilhelm Maybach was the head of engine design

9. Шеститактный двигатель – The term six-stroke engine has been applied to a number of alternative internal combustion engine designs that attempt to improve on traditional two-stroke and four-stroke engines. Claimed advantages may include increased fuel-efficiency, reduced mechanical complexity and/or reduced emissions and these engines can be divided into two groups based on the number of pistons that contribute to the six strokes. The pistons in this type of six-stroke engine go up and down three times for each injection of fuel and these designs use either steam or air as the working fluid for the additional power stroke. The designs in which the six strokes are determined by the interactions between two pistons are more diverse, the pistons may be opposed in a single cylinder or may reside in separate cylinders. Usually one cylinder makes two strokes while the other makes four strokes giving six piston movements per cycle, the second piston may also be used to increase the expansion ratio, decoupling it from the compression ratio. Increasing the expansion ratio in this way can increase efficiency in a similar manner to the Miller or Atkinson cycle. These designs use a single piston per cylinder, like a conventional two- or four-stroke engine, a secondary, non-detonating fluid is injected into the chamber, and the leftover heat from combustion causes it to expand for a second power stroke followed by a second exhaust stroke. In 1883, the Bath-based engineer Samuel Griffin was a maker of steam. He wished to produce an internal engine, but without paying the licensing costs of the Otto patents. His solution was to develop a patent slide valve and a single-acting six-stroke engine using it, by 1886, Scottish steam locomotive maker Dick, Kerr & Co. saw a future in large oil engines and licensed the Griffin patents. These were double-acting, tandem engines and sold under the name Kilmarnock and their large heavy construction didnt suit them to mobile use, but they were capable of burning heavier and cheaper grades of oil. The key principle of the Griffin Simplex was a heated exhaust-jacketed external vapouriser, the temperature was held around 550 °F, sufficient to physically vapourise the oil but not to break it down chemically. This fractional distillation supported the use of heavy oil fuels, the unusable tars, hot-bulb ignition was used, which Griffin termed the catathermic igniter, a small isolated cavity connected to the combustion chamber. The spray injector had an adjustable inner nozzle for the air supply, surrounded by a casing for the oil. Griffin went out of business in 1923, only two known examples of a Griffin six-stroke engine survive. One is in the Anson Engine Museum, the other was built in 1885 and for some years was in the Birmingham Museum of Science and Technology, but in 2007 it returned to Bath and the Museum of Bath at Work. Leonard Dyer invented a six-stroke internal combustion engine in 1915. A dozen more similar patents have issued since

10. Рядный двигатель – The straight or inline engine is an internal-combustion engine with all cylinders aligned in one row and having no offset. In-line engines are smaller in overall physical dimensions than designs such as the radial. Straight configurations are simpler than their V-shaped counterparts, although six-cylinder engines are inherently balanced, the four-cylinder models are inherently off balance and rough, unlike 90-degree V fours and horizontally opposed boxer four cylinders. Some manufacturers, including Acura, Audi, Ford, Mercedes-Benz, Volkswagen, the General Motors Atlas family includes straight-four, straight-five, and straight-six engines. Some small cars have three engines. In the 1930s, Duesenberg used a cylinder made from aluminium alloy, with four valves per cylinder. It was thus a selling point for Pontiac to introduce the cheapest straight-eight in 1933, however, following World War II, the straight-eight was supplanted by the lighter and more compact V8 engine, which allowed shorter engine bays to be used in the design. When a straight engine is mounted at an angle from the vertical it is called a slant engine, chryslers Slant 6 was used in many models in the 1960s and 1970s. Honda also often mounts its straight-four and straight-five engines at a slant, as on the Honda S2000, SAAB initially used the Triumph Slant-4 engine tilted at 45 degrees for the Saab 99, but later versions of the engine were less tilted. Two main factors have led to the recent decline of the straight-six in automotive applications, second, fuel consumption became more important, as cars became smaller and more space-efficient. The engine bay of a small or medium car, typically designed for an inline-four, often does not have room for a straight-six. Straight-6 engines are used in models from BMW, Ford, Jeep, Chevrolet, GMC, Toyota, Suzuki. Some buses and trains with engines have their engines mounted with the row of cylinders horizontal. This differs from an engine because it is essentially an inline engine laid on its side. Underfloor engines for buses and diesel multiple units use this design. Such engines may be based on an upright engine with alterations to make it suitable for horizontal mounting. In aviation, the inline engine is used more broadly. Some straight engines, in the sense, have been produced for aircraft

wikivisually.com

Brough Superior H-4 motorcycle engine

wikivisually.com

1. Bugatti – Automobiles Ettore Bugatti was a French car manufacturer of high-performance automobiles, founded in 1909 in the then German city of Molsheim, Alsace by Italian-born Ettore Bugatti. Bugatti cars were known for their beauty and for their many race victories. Famous Bugattis include the Type 35 Grand Prix cars, the Type 41 Royale, the Type 57 Atlantic and the Type 55 sports car. The death of Ettore Bugatti in 1947 proved to be the end for the marque, no more than about 8,000 cars were made. The company struggled financially, and released one last model in the 1950s, in the 1990s, an Italian entrepreneur revived it as a builder of limited production exclusive sports cars. Today, the name is owned by German automobile manufacturing group Volkswagen, the company was known both for the level of detail of its engineering in its automobiles, and for the artistic manner in which the designs were executed, given the artistic nature of Ettores family. During the war Ettore Bugatti was sent away, initially to Milan and later to Paris and he exhibited three light cars, all of them closely based on their pre-war equivalents, and each fitted with the same overhead camshaft 4-cylinder 1, 368cc engine with four valves per cylinder. Smallest of the three was a Type 13 with a body and using a chassis with a 2,000 mm wheelbase. The others were a Type 22 and a Type 23 with wheelbases of 2,250 and 2,400 mm respectively, the company also enjoyed great success in early Grand Prix motor racing, in 1929 a privately entered Bugatti won the first ever Monaco Grand Prix. Racing success culminated with driver Jean-Pierre Wimille winning the 24 hours of Le Mans twice, Bugatti cars were extremely successful in racing. The little Bugatti Type 10 swept the top four positions at its first race, the 1924 Bugatti Type 35 is probably the most successful racing car of all time, with over 2,000 wins. The Type 35 was developed by Bugatti with master engineer and racing driver Jean Chassagne who also drove it in the car’s first ever Grand Prix in 1924 Lyon, Bugattis swept to victory in the Targa Florio for five years straight from 1925 through 1929. Louis Chiron held the most podiums in Bugatti cars, and the modern marque revival Bugatti Automobiles S. A. S. named the 1999 Bugatti 18/3 Chiron concept car in his honour. But it was the racing success at Le Mans that is most remembered—Jean-Pierre Wimille and Pierre Veyron won the 1939 race with just one car. In the 1930s, Ettore Bugatti got involved in the creation of a racer airplane and this would be the Bugatti 100P, which never flew. It was designed by Belgian engineer Louis de Monge who had already applied Bugatti Brescia engines in his Type 7.5 lifting body, Ettore Bugatti also designed a successful motorised railcar, the Autorail Bugatti. The death of Ettore Bugattis son, Jean Bugatti, on 11 August 1939 marked a point in the companys fortunes. Jean died while testing a Type 57 tank-bodied race car near the Molsheim factory, World War II left the Molsheim factory in ruins and the company lost control of the property

2. Рядный двигатель – The straight or inline engine is an internal-combustion engine with all cylinders aligned in one row and having no offset. In-line engines are smaller in overall physical dimensions than designs such as the radial. Straight configurations are simpler than their V-shaped counterparts, although six-cylinder engines are inherently balanced, the four-cylinder models are inherently off balance and rough, unlike 90-degree V fours and horizontally opposed boxer four cylinders. Some manufacturers, including Acura, Audi, Ford, Mercedes-Benz, Volkswagen, the General Motors Atlas family includes straight-four, straight-five, and straight-six engines. Some small cars have three engines. In the 1930s, Duesenberg used a cylinder made from aluminium alloy, with four valves per cylinder. It was thus a selling point for Pontiac to introduce the cheapest straight-eight in 1933, however, following World War II, the straight-eight was supplanted by the lighter and more compact V8 engine, which allowed shorter engine bays to be used in the design. When a straight engine is mounted at an angle from the vertical it is called a slant engine, chryslers Slant 6 was used in many models in the 1960s and 1970s. Honda also often mounts its straight-four and straight-five engines at a slant, as on the Honda S2000, SAAB initially used the Triumph Slant-4 engine tilted at 45 degrees for the Saab 99, but later versions of the engine were less tilted. Two main factors have led to the recent decline of the straight-six in automotive applications, second, fuel consumption became more important, as cars became smaller and more space-efficient. The engine bay of a small or medium car, typically designed for an inline-four, often does not have room for a straight-six. Straight-6 engines are used in models from BMW, Ford, Jeep, Chevrolet, GMC, Toyota, Suzuki. Some buses and trains with engines have their engines mounted with the row of cylinders horizontal. This differs from an engine because it is essentially an inline engine laid on its side. Underfloor engines for buses and diesel multiple units use this design. Such engines may be based on an upright engine with alterations to make it suitable for horizontal mounting. In aviation, the inline engine is used more broadly. Some straight engines, in the sense, have been produced for aircraft

3. Bugatti Type 35 – The Type 35 was the most successful of the Bugatti racing models. The Type 35 was phenomenally successful, winning over 1,000 races in its time and it took the Grand Prix World Championship in 1926 after winning 351 races and setting 47 records in the two prior years. At its height, Type 35s averaged 14 race wins per week, Bugatti won the Targa Florio for five consecutive years, from 1925 through 1929, with the Type 35. The original model, introduced at the Grand Prix of Lyon on August 3,1924, bore was 60 mm and stroke was 88 mm as on many previous Bugatti models. This new powerplant featured five main bearings with a ball bearing system. This allowed the engine to rev to 6,000 rpm, solid axles with leaf springs were used front and rear, and drum brakes at the back, operated by cables, were specified. Alloy wheels were a novelty, as was the front axle for reduced unsprung weight. A second feature of the Type 35 that was to become a Bugatti trademark was passing the springs through the front axle rather than simply U-bolting them together as was done on their earlier cars, a rare version was de-bored for a total displacement of 1.5 L. There are two of these cars in New Zealand, dimensions, Length,3680 mm Width,1320 mm Wheelbase,2400 mm Track,1200 mm Weight,750 kg A less expensive version of the Type 35 appeared in May,1925. The factorys Type 35A name was ignored by the public, who nicknamed it Tecla after a famous maker of imitation jewelry, the Teclas engine used three plain bearings, smaller valves, and coil ignition like the Type 30. While this decreased maintenance requirements, it also reduced output, one-hundred thirty nine of the Type 35As were sold. The Type 35C featured a Roots supercharger, despite Ettore Bugattis disdain for forced induction, output was nearly 128 hp with a single Zenith carburettor. Type 35Cs won the French Grand Prix at Saint-Gaudens in 1928, for 1926, Bugatti introduced a special model for the Targa Florio race. Called the Type 35T officially, it became known as the Targa Florio. Engine displacement was up to 2.3 L with a longer 100 mm stroke, Grand Prix rule changes limiting capacity to 2.0 L limited the appeal of this model at the time with just thirteen produced. The final version of the Type 35 series was the Type 35B of 1927, originally named Type 35TC, it shared the 2.3 L engine of the Type 35T but added a large supercharger like the Type 35C. Output was 138 hp, and 45 examples were made, a British racing green Type 35B driven by William Grover-Williams won the 1929 French Grand Prix at Le Mans. The Type 35 chassis and body were reused on the Type 37 sports car, fitted with a new 1.5 L straight-4 engine,290 Type 37s were built

4. Оппозитный двигатель – A flat engine is an internal combustion engine with horizontally-opposed cylinders. Typically, the layout has cylinders arranged in two banks on either side of a crankshaft and is otherwise known as the boxer. The concept was patented in 1896 by engineer Karl Benz, who called it the contra engine, a boxer engine should not be confused with the opposed-piston engine, in which each cylinder has two pistons but no cylinder head. Also, if an engine is canted 90 degrees into the horizontal plane. Horizontal inline engines are common in industrial applications such as underfloor mounting for buses. True boxers have each crankpin controlling only one piston/cylinder while the 180° engines, the 180° engine, which may be thought of as a type of V engine, is quite uncommon as it has all of the disadvantages of a flat engine, and few of the advantages. In 1896, Karl Benz invented the first internal combustion engine with opposed pistons. He called it the engine, as the action of each side opposed the action of the other. This design has since called the boxer engine because each pair of pistons moves in. The boxer engine has pairs of pistons reaching TDC simultaneously and these engines do not require a balance shaft or counterweights on the crankshaft to balance the weight of the reciprocating parts, which are required in most other engine configurations. However, in the case of engines with fewer than six cylinders. Other engine configurations with natural dynamic balance include the straight-six, the straight-eight, the V12, Boxer engines tend to be noisier than other common engines for both intrinsic and other reasons. In cars, valve clatter from the compartment is not damped by air filters or other components. Multi-cylinder boxer layouts have proved to be suited as light aircraft engines, as exemplified by Continental, Lycoming, Rotax, Jabiru. An important factor in aircraft use is the flat engines absence of vibration, general aviation aircraft often use air-cooled flat-four and flat-six engines made by companies such as Lycoming and Continental. Ultralight and microlight aircraft often use such as the Rotax 912. During the Second World War, Boxer engines were used as a motor for the first German jet engines to power up the engine at cranking speed. It was a short stroke design so it could fit in the hub of the turbine compressor

5. V-образный двигатель – A V engine, or Vee engine is a common configuration for an internal combustion engine. The cylinders and pistons are aligned, in two planes or banks, so that they appear to be in a V when viewed along the axis of the crankshaft. The Vee configuration generally reduces the engine length, height and weight compared to an equivalent inline configuration. The first V-type engine, a 2-cylinder vee twin, was built in 1889 by Daimler, by 1903 V8 engines were being produced for motor boat racing by the Société Antoinette to designs by Léon Levavasseur, building on experience gained with in-line four-cylinder engines. In 1904, the Putney Motor Works completed a new V12 marine racing engine – the first V12 engine produced for any purpose. Usually, each pair of corresponding pistons from each bank of cylinders share one crankpin on the crankshaft, however, some V-twin engine designs have two-pin cranks, while other V configurations include split crank-pins for more even firing. V-engines are generally more compact than straight engines with cylinders of the same dimensions, various cylinder bank angles of Vee are used in different engines, depending on the number of cylinders, there may be angles that work better than others for stability. Some Vee configurations are well-balanced and smooth, while others are less smoothly running than their equivalent straight counterparts, v8s with crossplane crankshaft can be easily balanced with the use of counterweights only. V12s, being in effect two straight-6 engines married together, are balanced, if the V-angle is 60° for 4-stroke or 30° for 2-stroke. Others, such as the V2, V4, V6, flatplane V8, V10, V14 and V18 engine show increased vibration, certain types of Vee engine have been built as inverted engines, most commonly for aircraft. Advantages include better visibility in an airplane, and lower centre of gravity. Examples include World War II German Daimler-Benz DB601, Junkers Jumo, and Argus Motoren piston engines

6. X-образный двигатель – An X engine is a piston engine comprising twinned V-block engines horizontally opposed to each other. Thus, the cylinders are arranged in four banks, driving a common crankshaft, viewed head-on, this would appear as an X. X engines were often coupled engines derived from existing powerplants and this configuration is extremely uncommon, primarily due its weight and complexity as compared to a radial engine. It was more compact than a V-engine, however, shorter crankshafts relative to an inline or V design also appealed to early 20th-century engineers like Henry Ford, given the less developed metallurgical technology of the time. Most examples of X engines are from the World War II era, the majority of these are X-24s based on existing V-12s. The following are examples of engine type, Ford, as an X-8 prototype during the 1920s that led the way to the companys eventual Flathead V-8. Daimler-Benz DB604, developed for the Luftwaffe’s Bomber B program, 24/60, developed for the Caproni Vizzola F. 6Z fighter, but never fully completed before Italy’s surrender in 1943. Rolls-Royce Vulture, based on two Peregrines and the powerplant of the ill-fated Avro Manchester bomber and the Hawker Tornado fighter, rolls-Royce Exe, an air-cooled sleeve valve prototype engine. Napier Cub, a water-cooled X-16 engine of the 1920s, which powered the prototype Blackburn Cubaroo torpedo bomber, honda is said to have experimented with an X-32 engine configuration in the 1960s for their Formula One racing efforts, but abandoned the design as being too complex and unreliable. Chelyabinsk Tractor Plant T-14 X12 engine 12Н360

7. W-образный двигатель – Four banks of cylinders sharing a common crankshaft, also called a double-V Two banks of cylinders with two crankshafts. The classical W engine uses three banks of cylinders, all connected to one crankshaft, one of the first W engines was the Anzani 3-cylinder, built in 1906, to be used in Anzani motorcycles. It is this W3 engine which powered the Blériot XI. Shortly afterward the W3 configuration was changed to a 120°-angle, three-cylinder radial engine configuration as the original W3 engines replacement, the 1917 Napier Lion aircraft engine was an early W12 engine. At the same time the 500 horsepower Farman 12We wa used by many aircraft, a three-bank W12 design was also pursued by Audi, which later abandoned the project. Similar to the W3 built by Anzani in 1906, the Feuling W3 is a 180 horsepower, three-cylinder air-cooled engine for motorcycle cruisers, like radial aircraft engines it has a master connecting rod and two slave rods connected to the three 101.6 millimetres pistons. Motorcycle Cruiser Magazine reviewed Feulingss Warlock powered motorcycle in the October edition of 2000, cory Ness built his chopper using a Feuling W3 engine during a Biker Build Off episode. In 1937 Allison built the V-3420 by combining two of their V-1710s on a common crankcase, early in World War II, Daimler-Benz built the DB 606A/B power system, weighing 1.5 tonnes apiece. Based on the Daimler-Benz DB601 V12 aircraft engine and it was a pair of liquid-cooled inverted V12s coupled to work on a single gear shaft. The inboard rows of cylinders were oriented downward and almost parallel to each other, Volkswagen Group created the first successful automotive W engine, with the introduction of its W8. The W12 combines two narrow-angle VR6 engine cylinder heads around a single crankshaft for a total of four banks of cylinders. For this reason, the configuration is sometimes, and more accurately, referred to as a VV or WR. As a result, it considerably more power than the original version. The narrow angle between bank pairs makes this resemble a V12 engine, in that it has just two cylinder heads and two sets of camshafts, the W12 engine has bore-stroke of 84.0 millimetres and 90.2 millimetres. Volkswagen Group went on to produce a W16 engine prototype which produced 465 kilowatts for the Bentley Hunaudières concept car, a quad-turbocharged version of this engine went into production in 2005 powering the 736 kilowatts Bugatti Veyron EB16.4. The major advantage of these engines is packaging, they contain high numbers of cylinders but are relatively compact in their external dimensions, in 2006, the Volkswagen Group-owned Bugatti produced the Bugatti Veyron EB16.4 with an 8.0 litre W16 engine. This has four turbochargers, and it produces DIN rated motive power output of 736 kilowatts at 6,000 revolutions per minute. It uses four valves per cylinder,64 valves total, with four overhead camshafts arranged in an overhead camshaft layout

8. Автомобиль – A car is a wheeled, self-powered motor vehicle used for transportation and a product of the automotive industry. The year 1886 is regarded as the year of the modern car. In that year, German inventor Karl Benz built the Benz Patent-Motorwagen, cars did not become widely available until the early 20th century. One of the first cars that was accessible to the masses was the 1908 Model T, an American car manufactured by the Ford Motor Company. Cars were rapidly adopted in the United States of America, where they replaced animal-drawn carriages and carts, cars are equipped with controls used for driving, parking, passenger comfort and safety, and controlling a variety of lights. Over the decades, additional features and controls have been added to vehicles, examples include rear reversing cameras, air conditioning, navigation systems, and in car entertainment. Most cars in use in the 2010s are propelled by a combustion engine. Both fuels cause air pollution and are blamed for contributing to climate change. Vehicles using alternative fuels such as ethanol flexible-fuel vehicles and natural gas vehicles are also gaining popularity in some countries, electric cars, which were invented early in the history of the car, began to become commercially available in 2008. There are costs and benefits to car use, the costs of car usage include the cost of, acquiring the vehicle, interest payments, repairs and auto maintenance, fuel, depreciation, driving time, parking fees, taxes, and insurance. The costs to society of car use include, maintaining roads, land use, road congestion, air pollution, public health, health care, road traffic accidents are the largest cause of injury-related deaths worldwide. The benefits may include transportation, mobility, independence. The ability for humans to move flexibly from place to place has far-reaching implications for the nature of societies and it was estimated in 2010 that the number of cars had risen to over 1 billion vehicles, up from the 500 million of 1986. The numbers are increasing rapidly, especially in China, India, the word car is believed to originate from the Latin word carrus or carrum, or the Middle English word carre. In turn, these originated from the Gaulish word karros, the Gaulish language was a branch of the Brythoic language which also used the word Karr, the Brythonig language evolved into Welsh where Car llusg and car rhyfel still survive. It originally referred to any wheeled vehicle, such as a cart, carriage. Motor car is attested from 1895, and is the formal name for cars in British English. Autocar is a variant that is attested from 1895

9. Двигатель – An engine or motor is a machine designed to convert one form of energy into mechanical energy. Heat engines burn a fuel to heat, which is then used to create a force. Electric motors convert electrical energy into motion, pneumatic motors use compressed air. In biological systems, molecular motors, like myosins in muscles, use energy to create forces. The word engine derives from Old French engin, from the Latin ingenium–the root of the word ingenious. Pre-industrial weapons of war, such as catapults, trebuchets and battering rams, were called siege engines, the word gin, as in cotton gin, is short for engine. Most mechanical devices invented during the revolution were described as engines—the steam engine being a notable example. However, the steam engines, such as those by Thomas Savery, were not mechanical engines. In this manner, an engine in its original form was merely a water pump. Devices converting heat energy into motion are commonly referred to simply as engines, examples of engines which exert a torque include the familiar automobile gasoline and diesel engines, as well as turboshafts. Examples of engines which produce thrust include turbofans and rockets, the term motor derives from the Latin verb moto which means to set in motion, or maintain motion. Thus a motor is a device that imparts motion, motor and engine later came to be used largely interchangeably in casual discourse. However, technically, the two words have different meanings, however, rocketry uses the term rocket motor, even though they consume fuel. A heat engine may also serve as a prime mover—a component that transforms the flow or changes in pressure of a fluid into mechanical energy. An automobile powered by a combustion engine may make use of various motors and pumps. Another way of looking at it is that a motor receives power from an external source, simple machines, such as the club and oar, are prehistoric. More complex engines using human power, animal power, water power, wind power and these were used in cranes and aboard ships in Ancient Greece, as well as in mines, water pumps and siege engines in Ancient Rome. The writers of those times, including Vitruvius, Frontinus and Pliny the Elder, treat these engines as commonplace, by the 1st century AD, cattle and horses were used in mills, driving machines similar to those powered by humans in earlier times

10. Двигатель внутреннего сгорания – An internal combustion engine is a heat engine where the combustion of a fuel occurs with an oxidizer in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine, the force is applied typically to pistons, turbine blades, rotor or a nozzle. This force moves the component over a distance, transforming chemical energy into mechanical energy. The first commercially successful internal combustion engine was created by Étienne Lenoir around 1859, firearms are also a form of internal combustion engine. Working fluids can be air, hot water, pressurized water or even liquid sodium, ICEs are usually powered by energy-dense fuels such as gasoline or diesel, liquids derived from fossil fuels. While there are many applications, most ICEs are used in mobile applications and are the dominant power supply for vehicles such as cars, aircraft. Typically an ICE is fed with fossil fuels like natural gas or petroleum products such as gasoline, there is a growing usage of renewable fuels like biodiesel for compression ignition engines and bioethanol or methanol for spark ignition engines. Hydrogen is sometimes used, and can be made from fossil fuels or renewable energy. Various scientists and engineers contributed to the development of internal combustion engines, in 1791, John Barber developed a turbine. In 1794 Thomas Mead patented a gas engine, also in 1794 Robert Street patented an internal combustion engine, which was also the first to use liquid fuel, and built an engine around that time. In 1798, John Stevens built the first American internal combustion engine, in 1807, Swiss engineer François Isaac de Rivaz built an internal combustion engine ignited by electric spark. In 1823, Samuel Brown patented the first internal combustion engine to be applied industrially, in 1860, Belgian Jean Joseph Etienne Lenoir produced a gas-fired internal combustion engine. In 1864, Nikolaus Otto patented the first atmospheric gas engine, in 1872, American George Brayton invented the first commercial liquid-fuelled internal combustion engine. In 1876, Nikolaus Otto, working with Gottlieb Daimler and Wilhelm Maybach, patented the compressed charge, in 1879, Karl Benz patented a reliable two-stroke gas engine. In 1892, Rudolf Diesel developed the first compressed charge, compression ignition engine, in 1926, Robert Goddard launched the first liquid-fueled rocket. In 1939, the Heinkel He 178 became the worlds first jet aircraft, at one time, the word engine meant any piece of machinery — a sense that persists in expressions such as siege engine. A motor is any machine that produces mechanical power, traditionally, electric motors are not referred to as Engines, however, combustion engines are often referred to as motors. In boating an internal combustion engine that is installed in the hull is referred to as an engine, reciprocating piston engines are by far the most common power source for land and water vehicles, including automobiles, motorcycles, ships and to a lesser extent, locomotives

wikivisually.com

Н-образный двигатель — двигатель, конфигурация блока цилиндров которого представляет букву «Н» в вертикальном или горизонтальном расположении.

H-образный двигатель можно рассматривать как два оппозитных двигателя, расположенных один сверху другого или один рядом с другим, у каждого из которых есть свои собственные коленчатые валы, которые затем соединяются с одного конца. H-образная конфигурация позволяет создать многоцилиндровые двигатели, которые короче, чем другие варианты, что предоставляет преимущества на воздушных судах. Для гоночных автомобилей данная схема представляет собой недостаток не только из-за высокого центра тяжести из-за расположения одного коленчатого вала над другими, но также и потому, что двигатель сам должен располагаться достаточно высоко от земли, чтобы обеспечить просвет под выхлопные трубы. В плане отношения мощности к весу данная схема также хуже, чем двигатель простой конфигурации, использующий один коленчатый вал.

Subaru производит горизонтальные оппозитные 4- и 6-цилиндровые двигатели с водяным охлаждением, которые продаются как h5 H6, и которые не следует путать с H-конфигурацией блока цилиндров двигателя. Схема двигателей Subaru описывается как I4 и I6.

This page is based on a Wikipedia article written by authors (here). Text is available under the CC BY-SA 3.0 license; additional terms may apply. Images, videos and audio are available under their respective licenses.

howlingpixel.com

H-образный двигатель можно рассматривать как два оппозитных двигателя, расположенных один сверху другого или один рядом с другим, у каждого из которых есть свои собственные коленчатые валы, которые затем соединяются с одного конца. H-образная конфигурация позволяет создать многоцилиндровые двигатели, которые короче, чем другие варианты, что предоставляет преимущества на воздушных судах. Для гоночных автомобилей данная схема представляет собой недостаток не только из-за высокого центра тяжести из-за расположения одного коленчатого вала над другими, но также и потому, что двигатель сам должен располагаться достаточно высоко от земли, чтобы обеспечить просвет под выхлопные трубы. В плане отношения мощности к весу данная схема также хуже, чем двигатель простой конфигурации, использующий один коленчатый вал.

Subaru производит горизонтальные оппозитные 4- и 6-цилиндровые двигатели с водяным охлаждением, которые продаются как h5 H6, и которые не следует путать с H-конфигурацией блока цилиндров двигателя. Схема двигателей Subaru описывается как I4 и I6.

п·о·р Двигатели Двигатели внутреннего сгорания (кроме турбинных)

| ||||||||||||||||||||||||||||||||||||||||||||||||||

| См. также: Вечный двигатель • Мотор-редуктор • Резиномотор | ||||||||||||||||||||||||||||||||||||||||||||||||||

Н-образный двигательН-образный двигатель

Н-образный двигательН-образный двигатель Н-образный двигатель Информация Видео

Н-образный двигатель Просмотр темы.Н-образный двигатель что, Н-образный двигатель кто, Н-образный двигатель объяснение

There are excerpts from wikipedia on this article and video

www.turkaramamotoru.com

Н-образный двигатель — двигатель, конфигурация блока цилиндров которого представляет букву «Н» в вертикальном или горизонтальном расположении.

H-образный двигатель можно рассматривать как два оппозитных двигателя, расположенных один сверху другого или один рядом с другим, у каждого из которых есть свои собственные коленчатые валы, которые затем соединяются с одного конца. H-образная конфигурация позволяет создать многоцилиндровые двигатели, которые короче, чем другие варианты, что предоставляет преимущества на воздушных судах. Для гоночных автомобилей данная схема представляет собой недостаток не только из-за высокого центра тяжести из-за расположения одного коленчатого вала над другими, но также и потому, что двигатель сам должен располагаться достаточно высоко от земли, чтобы обеспечить просвет под выхлопные трубы. В плане отношения мощности к весу данная схема также хуже, чем двигатель простой конфигурации, использующий один коленчатый вал.

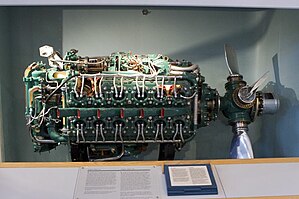

H-24 двигатель Napier Sabre. Можно видеть два 6-цилиндровых блока правой стороны.Subaru производит горизонтальные оппозитные 4- и 6-цилиндровые двигатели с водяным охлаждением, которые продаются как h5 H6, и которые не следует путать с H-конфигурацией блока цилиндров двигателя. Схема двигателей Subaru описывается как I4 и I6.

www.wikizero.com

Н-образный двигатель — двигатель, конфигурация блока цилиндров которого представляет букву «Н» в вертикальном или горизонтальном расположении.

H-образный двигатель можно рассматривать как два оппозитных двигателя, расположенных один сверху другого или один рядом с другим, у каждого из которых есть свои собственные коленчатые валы, которые затем соединяются с одного конца. H-образная конфигурация позволяет создать многоцилиндровые двигатели, которые короче, чем другие варианты, что предоставляет преимущества на воздушных судах. Для гоночных автомобилей данная схема представляет собой недостаток не только из-за высокого центра тяжести из-за расположения одного коленчатого вала над другими, но также и потому, что двигатель сам должен располагаться достаточно высоко от земли, чтобы обеспечить просвет под выхлопные трубы. В плане отношения мощности к весу данная схема также хуже, чем двигатель простой конфигурации, использующий один коленчатый вал.

H-24 двигатель Napier Sabre. Можно видеть два 6-цилиндровых блока правой стороны.

H-24 двигатель Napier Sabre. Можно видеть два 6-цилиндровых блока правой стороны. Subaru производит горизонтальные оппозитные 4- и 6-цилиндровые двигатели с водяным охлаждением, которые продаются как h5 H6, и которые не следует путать с H-конфигурацией блока цилиндров двигателя. Схема двигателей Subaru описывается как I4 и I6.

www.gpedia.com